Discover the Product-Family of Carbon-Drive

ENTIRE CARBON MOTOR SPINDLES

HSK 32 up to HSK 63

- Energy Efficiency: With over 50% weight reduction, our motor spindles minimize energy consumption. Say goodbye to unnecessary power drain and hello to cost savings!

- Dynamic Machining: Reduced inertia means lightning-fast response times. Whether you’re milling, drilling, or grinding, our spindles ensure optimal performance.

- Thermal Stability: Zero thermal expansion ensures consistent accuracy. No more tool center movement during critical operations.

The data speaks for itself. Now it’s up to you. You determine the size and performance. We just need your input.

CARBON DRIVE SHAFTS & ROTOR SLEEVES

we keep your magnets safe

Direct Winding of cfrp sleeves:

We engineered a specialized machine to wind the carbon fiber at extremely high tension. This ensures a snug fit, preventing any loosening at low temperatures. No compromises—just optimal performance. Our sleeves can handle high revolutions per minute (RPM) while maintaining a tight gap

Carbon-Drive shaft:

You are looking for less inertia to reach maximum speed within a second. We have the know-how to mount the magnets directly onto the shaft and make them suitable for your electric motor.

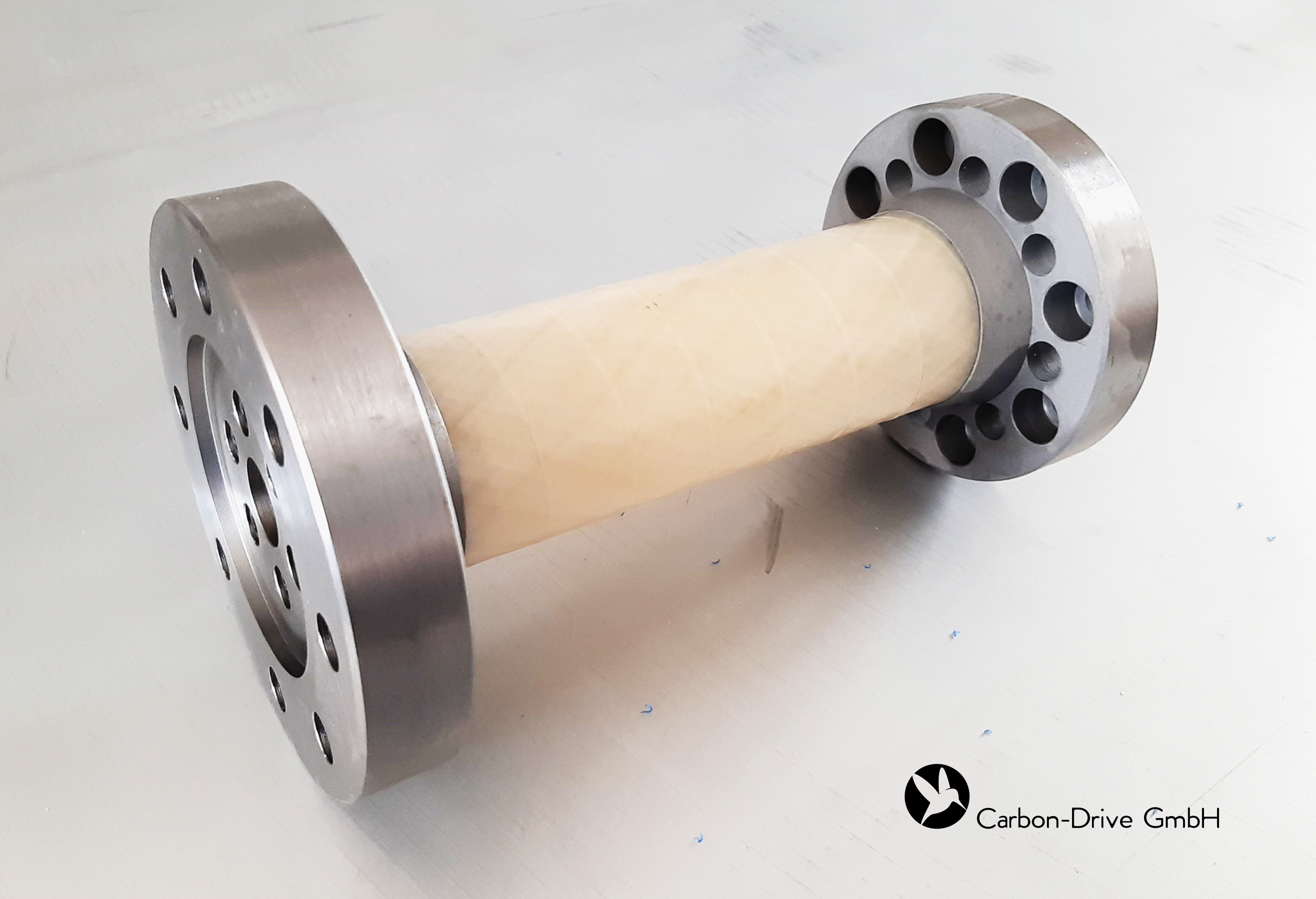

HIGH SPEED CARBON COUPLINGS

up to 5m lenght

- Custom Drive Systems:

- Wondering how to drive your test specimen effectively? Our team designs tailored drive systems that match your unique requirements. Whether it’s precision control, high torque, or variable speeds, we’ve got you covered.

- Vibration and Damping Expertise:

- Tired of disruptive vibrations? Our experts analyze and mitigate vibrations, ensuring smooth operation. We’ll fine-tune damping characteristics to enhance stability and reduce noise.

- Stiffness Optimization:

- Need rock-solid stiffness? We’ll optimize your system to withstand the toughest conditions. From material selection to structural design, our solutions ensure robust performance.

- Thermal Expansion Solutions:

- Thermal challenges? Our designs account for expansion and contraction. We’ll help you maintain accuracy even under extreme temperature variations.

- Swinging Mass Solutions:

- High swinging mass causing headaches? Let us balance it out! Our engineering marvels stabilize swinging masses, improving overall system performance.

- Strength Enhancement:

- Seeking higher strength? Our materials expertise and structural analysis empower your components to handle heavy loads and demanding environments.

CARBON TOOL HOLDER

Reduce your tilting moment and stable cutting process

Tool holders play a crucial role in machining processes, ensuring the secure attachment of cutting tools to the machine.

A long and slender tool holder made of steel has inherent limitations due to its mass-to-stiffness ratio. If the tool holder becomes too heavy or too large, the motor spindle may struggle to securely hold it during machining processes. This issue becomes more pronounced when the tool rotates at high speeds. Whether you’re performing deep hole drilling, milling, or grinding, our technology can assist you in advancing your machining capabilities. Let’s move forward together